Dlaczego Zigler?

Z prawdziwą przyjemnością przedstawiamy Państwu firmę ZIGLER POLSKA. Jesteśmy przekonani, że poniższe informacje przybliżą Państwu naszą firmę oraz zachęcą do rozpoczęcia współpracy z nami.

KNOW-HOW:

Chciałbyś produkować aerozole i nie wiesz jak zacząć?

Aktualności

Obszary w których działamy

Aerozole

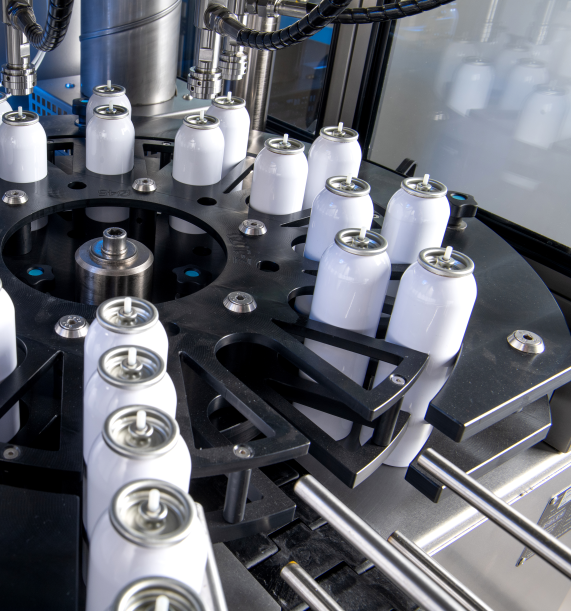

W zakres oferty ZIGLER zawierającej maszyny i urządzenia do napełniania aerozoli wchodzi kilka segmentów urządzeń.

Poniżej przedstawiamy podstawowy podział ze względu na wydajność:

- Linie półautomatyczne / laboratoryjne

- Pojedyncze moduły automatycznego napełniania (BASIC)

- Linie automatyczne o wydajności do 30 szt/min

- Linie automatyczne o wydajności do 60 szt/min

- Linie automatyczne o wydajności do 120 szt/min

- Linie automatyczne o wydajności w zakresie 120 szt/min – 250 szt/min – ZIGMAT

Bag-on-valve

BAG-ON-VALVE to innowacyjna technologia w wyrobach aerozolowych. Ma ona wiele zalet w porównaniu do rozwiązań z typowymi zaworami . Znajduje zastosowanie szczególnie w wyrobach farmaceutycznych oraz kosmetykach luksusowych a także takich preparatach , które nie mogą mieć styczności z gazem pędnym.

W ofercie ZIGLER POLSKA znajdują się urządzenia oraz całe linie produkcyjne do aerozoli w technologii BOV w następujących konfiguracjach:

- Linie półautomatyczne o wydajności do 500 szt/h

- Automaty (BASIC) o wydajności do 1200 szt/h

- Linie automatyczne o wydajności do 2400 szt/h

- Linie automatyczne o wydajności do 3600 szt/h

Maszyny do farmacji

ZIGLER oferuje pojedyncze urządzenia jak i całe linie technologiczne dla farmacji. Każda linia jest stworzona zgodnie z indywidualnymi wytycznymi klienta.

Oferujemy urządzenia i maszyny dla następujących typów opakowań:

- Standardowe aerozole (np. leki na oparzenia, dezynfekcyjne)

- MDI (METHERED DOSED INHLAERS)

- Aerozole w BOV (np. maści, kremy)

- Z zamknięciami typu Snap-on (np. krople do oczu)

- Zakręcane zamknięcia (np. preparaty w butelkach szklanych lub z tworzywa tj. syropy, krople etc.)

- Butelki z atomizerami (np. atomizer na ból gardła)

Linie nalewająco-zamykające

Oferta firmy ZIGLER to nie tylko aerozole. Oferujemy również automatyczne linie rozlewnicze oraz zakręcające. Każdą linię projektujemy w zależności do potrzeb oraz wymagań naszych klientów.

W naszej ofercie posiadamy:

- Automatyczne linie do konfekcjonowania kremów w opakowaniach 50 – 200 ml

- Automatyczne linie rozlewnicze do produktów chemiczno-kosmetycznych w opakowaniach o pojemności 50 ml – 2 l

- Automatyczne linie rozlewnicze do produktów gęstych typu żel o pojemności 100 – 500 ml

Linie do napełniania opakowań z atomizerami

Oferta firmy ZIGLER zawiera szereg urządzeń do konfekcjonowania perfum z atomizerami. Znajdą Państwo następujące konfiguracje:

- Linie półautomatyczne/laboratoryjne do 500 szt/h

- Pojedyncze moduły automatycznego napełniania (MRI 110/16) do 2400 szt/h

- Linie automatyczne do 3600 szt/h

Doradztwo aerozolowe

Oddajemy do dyspozycji naszą wiedzę oraz doświadczenie wszystkim, którzy dopiero zaczynają „przygodę” z aerozolami. Dotyczy to pełnego serwisu i obsługi posprzedażowej , przygotowania technologii danych produktów, doradztwa technicznego przy budowie zakładów produkcyjnych, szkolenia obsługi jak również pomocy przy doborze i zakupie komponentów niezbędnych do produkcji aerozoli.

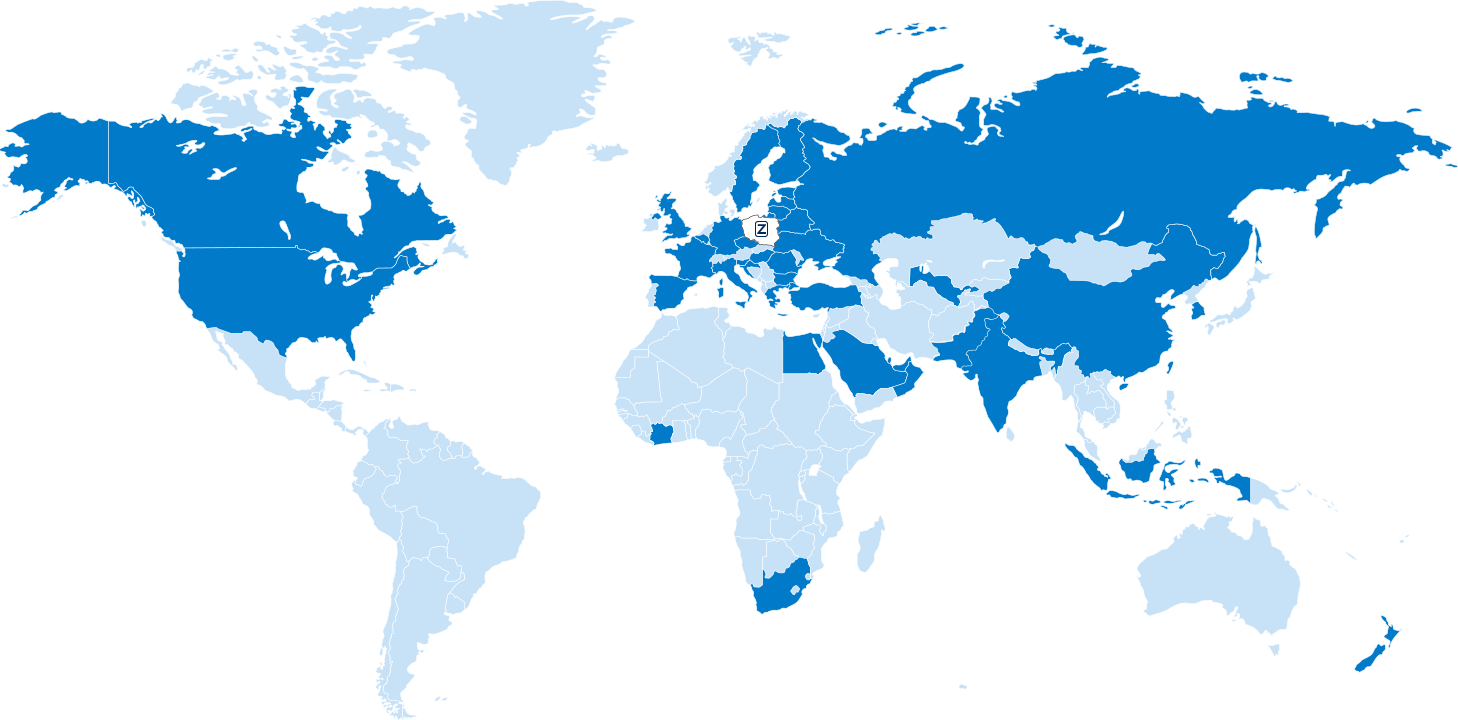

Działamy na całym świecie

- Polska

- Węgry

- Nowa Zelandia

- ZEA

- Niemcy

- Szwecja

- Indie

- Turcja

- Francja

- Wielka Brytania

- Indonezja

- Szwajcaria

- Hiszpania

- Rosja

- Białorus

- Egipt

- Włochy

- RPA

- Ukraina

- więcej....